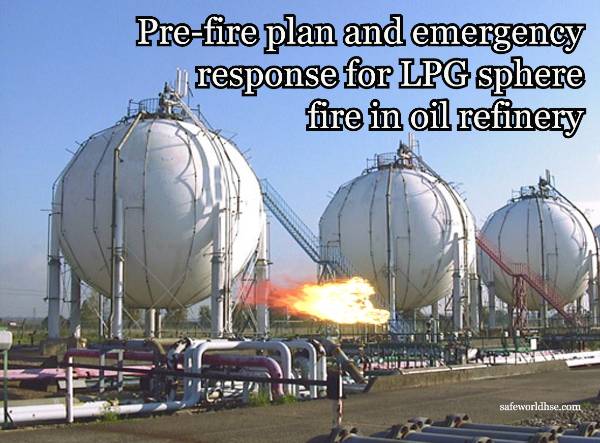

Pre-fire plan and emergency response for LPG sphere fire in oil refinery

Pre-fire plan and emergency response for LPG sphere fire in oil refinery

The pre-fire plan and emergency response

strategy are crucial at oil refineries, petrochemical and oil & Gas

terminals to mitigate any gas leak, fire and explosion emergency. The pre-fire

plan helps emergency responders to manage any emergency efficiently by

identifying the proactive mitigation actions for each credible identified

emergency scenario and thus helps to minimize the losses.

The storage of Liquefied Petroleum Gas (LPG) possess high risk of fire and

explosion due to its flammability property and may form vapour cloud at ground

level due to its high density.

This article provides information on effective emergency

response by preparing a pre-fire plan and the best firefighting

strategies for LPG fire and explosion emergencies for bulk

storage.

In this article, we will discuss the different credible

emergency scenarios in handling and storage of LPG and action plan to mitigate

these emergencies by improving the implementation and practice of the pre-fire

plan (PFP) or the pre-incident plan (PIP). We start with the general handling

and storage process of LPG, associated hazards, Fire protection system, emergency

response planning and firefighting strategies.

LPG storage facility in refinery

LPG is mixture of propane and butane and is stored in

bulk quantity at refinery and gas terminals, mostly stored in pressurised

vessels and Horton spheres from where it is transferred to LPG gantry for wagon

filling. Mounded vessels are also used for storing the LPG in some

installations. In some refinery, LPG is

directly transported to market through fixed pipeline from storage facility.

Hazard associated with LPG storage and handling

Below

are the major hazards of LPG bulk storage

·

Fire Hazard- Jet Fire/Flash

Fire

·

Explosion –UVCE and

BLEVE and secondary fires

·

Formation of vapour

cloud due to its higher density.

Boiling Liquid Expanding Vapour Explosion (BLEVE): It is an explosion of

container (sphere, vessel, tanker, cylinder, etc) containing flammable

liquid/liquefied gas caused by over pressurization due to boiling of the

liquid. This usually occurs due to the prolonged heating of the container and

liquid/ liquefied material reached at its boiling point, therefore the

conversion rate from liquid to vapour is

higher than the release rate through safety relief valve/ vent, which increases

the pressure inside the container. In addition, when the liquid converted to

gas, it expands and creates more pressure inside the container, for example,

expansion ratio of LPG from liquid phase to vapour phase is 1: 270 (i.e. 1

liter of liquid expands to 270 liters of vapour/gas).

Three main factors responsible for BLEVE, one is the over

pressurization due to the boiling of liquid, the second vaporization rate is

more than venting and the third is material loose it’s tensile strain due to

prolong heating by an external flame.

These three factors resulted in a catastrophic rupture of

container and the pressurized flammable vapour released suddenly in the form of

massive explosion called BLEVE.

A secondary fire in nearby facility can be caused by shock

wave and propelled pieces of container.

Unconfined vapour cloud explosion (UVCE):

It is a delayed explosion of released flammable vapor/ gas away from point of

leak source after the formation of flammable mixture in an unconfined area.

UVCE occurred when flammable gas released into the atmosphere,

after some delay, forms a vapour cloud and ignited by ignition source away from

its point of leak source resulted into deflagration.

In UVCE, the flame propagate at an ultrasonic velocity thus

produces shock waves and destroys the entire installation covered under the

cloud.

A secondary fire in the facility can be caused by shock wave

and direct contact of fire and explosion.

If the gas is heavier than air (LPG, vapours of gasoline,

diesel, kerosene and other hydrocarbons), the flammable cloud covers more area

whereas lighter gas (hydrogen, methane, etc) forms less flammable cloud because

it disperses easily.

Flash fire: It is the ignition of flammable

vapour/gas mixture within its flammable range immediately after it’s released

from the source. This type of fire doesn’t cause an explosion, but the flame

burns back against vopour cloud.

Jet fire: The release of gas, vapor, or

liquid from the container above atmospheric pressure and causes a fire due to

ignition, called as jet fire. It is a 3D fire in the form of a jet.

Safety consideration in LPG storage facility

LPG

Horton spheres or vessels are placed into groups and each group is limited to

six spheres/vessels.

Storage

quantity of each group is limited to 15000 M3 and curb wall provided around the

storage area for containment of leakage. Storage spheres/ vessels are installed

in single row and vessels/ bullets must not be stacked one above the other All

storage spheres/ vessels are separated from each other in same group or from

adjacent group by minimum distance of 30 meters. Minimum 30 meter separation

distance maintained form group to group also.

In case

of LPG vessel, installation should be such that the longitudinal axes of

horizontal vessels or bullets must not be pointed toward any other process

facility, equipment or other LPG storage container.

LPG storage

facility should not be located upwind of process units’ heaters/ furnace.

Therefore, it must be placed in downwind of process units so that in case of

any leakage, vapour cloud should not be travel toward process unit to prevent

source of ignition.

LPG

storage tanks (sphere/vessel/bullate) are

not installed along with other liquid hydrocarbons storage tanks in same dyke.

Shallow sump for LPG spillage collection is generally located at a safe distance

to prevent flame propagation from sump in case of fire event. Typically,

15-meter distance is considered as safe for this sump, but the distance may be

vary by considering adjacent storage tank diameter.

The

height of curb wall around the LPG storage tank is limited to minimum 30cm and

maximum 60 cm.

Safe

separation distance of LPG bulk storage should be maintained during designing

stage and it must not be less than 60 meters from process units, control

building and any electrical substations.

Separation

distance from flare, fire stations and process unit heater/ furnace must not be

less than 90 meters whereas it should not be less than 30 meters from nearest

oil storage area, loading gantries and rail spurs.

Access

roads suitable for fire engines by considering turning radius is provided all

around the storage facility.

Inspection

and testing of safety relief devices is important along with other critical

safety equipment and devices. Adequate process control is necessary to protect

against LPG leakage during water draining activity and other maintenance work.

Credible Emergency Scenarios for LPG Storage

·

Jet Fire / Flash fire in case of leakage and

ignition within short time.

·

Pool fire in LPG if major leak from bottom of

storage

·

Formation of vaplour cloud due to leak without

fire and cover huge area upto 2 Km

·

Vapour cloud explosion due to delayed ignition

and secondary fires

·

BLEVE due to the prolonged

heating by flame impingement

to storage tank shell and secondary fires.

Fire protection system for LPG storage facility

Entire

LPG storage facility is provided with fire water ring main with fire water

hydrants and water monitors. Fire water header pressure is mostly maintained at

10.5 kg/cm2 at all time. Automatic water spray deluge system is provided for

all LPG storage spheres/ vessel covering compressors/ pumps and important

isolation valves. Flow rate of water spray system is 10.2 lpm/m2 for storage

tank and 20.4 lpm/m2 for compressor and pumps.

Portable

DCP fire extinguishers are provided in storage facility as per NFPA-10. Trolley

mounted dry chemical power extinguishers of capacity 50 kg/ 75 kg are provided

at compressor and pump area.

DCP

mobile fire engine of capacity 4ooo kg is provided at fire station for LPG

firefighting. Entire area of LPG storage is provided with gas detectors for

early detection and communication. Manual call points provided in the area for

emergency alarming and communication to fire department.

Refinery emergency response plan for LPG storage fire

Planning for emergency preparedness and

response at a refinery is an important document developed with

reference to the quantitative risk assessment (QRA), including modelling of gas

dispersion.

Here in this article we are discussing the emergency

response plan for the LPG Horton sphere only.

The emergency response plan must include the mitigation measures

by the operations team, the maintenance team, the site incident controller, the

security team, the firefighting crew and the medical team applicable to all

credible scenarios.

Now we are discussing here the common course of actions

for all types of LPG emergencies by each key member.

Emergency response plan - Action by the operational team:

In the event of an emergency, by any person, activate the nearby

manual call point (MCP) and simultaneously transmit the message to the operator

of the control panel and operational Shift In charge of storage-sales and

dispatch area (SSDA) via Walkie Talkie.

The control room panel officer must inform the respective plant

manager, the chief operating officer and the manager of the refinery shift.

The SSDA panel officer must inform the panels officer of neighboring

units. Then, he must make an announcement via the public address system to stop

all work and evacuate the area immediately.

The operating team, including the field officer and the site

manager, initiates mitigation measures based on the LPG leak without fire or

with fire scenario.

Simultaneously, the operations team must initiate isolation of

the LPG sphere, stop the loading/ unloading activity of affected area including

gantry operation.

The operation team should assist the firefighting team and the

medical team by directing them to the emergency scene. The initial firefighting

or any other mitigation measure must be initiated by the operating team, viz.

operation of fire extinguishers, water spray system for cooling all LPG spheres

in the group , operation of fire monitors and fire hydrant, etc.

The operating team must monitor the LEL concentration during

the emergency and after completion.

Operation in charge must maintain constant communication with

the site incident controller on the measures taken and must work under the

direction of the site incident controller.

Emergency

action by Site Incident Controller

Upon receipt of the emergency call, the site incident

controller must reach the incident site and assume overall command in

accordance with the refinery's emergency response and disaster

management plan.

Assess the situation, establish the command post in a safe

place and obtain all the information on the measures taken by the area manager

/ shift manager, the fire commander, the security officer and the maintenance in-charge.

Depending on the situation, site incident controller will

guide the operating team to initiate the necessary isolation or the emergency shutdown

of facility, if necessary. Site incident controller must ensure that all of the

above emergency actions have been taken by the operations team.

The site incident controller will take all relevant

information from the fire commander and decide on the strategy to follow in

consultation with Fire chief for additional resources, calling for mutual aid

and adopting alternative methods to mitigate the emergency.

The site incident controller must ensure that the area is

barricaded, that the movement of vehicles is restricted, that evacuation and

enumeration at the assembly point are done by security team.

The site incident controller must request the maintenance team

to perform a maintenance activity to stop the leak in accordance with their

standard operating procedures.

He must ensure that the injured person has been transferred to

the health center and also ensure the availability of first aiders and

auxiliary firefighters.

The site incident controller must initiate an adequate level

of emergency siren after discussion with the chief incident controller (Refinery

Head).

He is responsible for declaring "All Clear" after

ensuring the safe mitigation of the emergency. Before declaring “All Clear”, he

must assess the situation for damage and the environment.

Emergency

mitigation action by Maintenance Team

The maintenance leader must ensure that the maintenance team

immediately reaches the incident site with the necessary non-sparking tools and

resources in accordance with their standard operating procedures and initiates

the action line in accordance with safe maintenance practices.

Maintenance in charge must report to the site incident

controller and issue directives for the continuation of the maintenance

activities to be carried out.

Emergency

action by Security Team:

The security officer must report to the incident site

immediately after receiving an emergency call and report to the site incident

controller.

They must delimit the area and restrict the movement of

non-essential people. They must regulate traffic and authorize only emergency

vehicles on the emergency site.

Ensure an orderly evacuation to the assembly point. A security

officer counts the workforce and rebroadcasts it to the site incident

controller.

All emergency team leaders must ensure the safety of their

team members and mandatory PPE is used.

So far, we have discussed the general course of action of all

key personnel to mitigate any type of emergency in LPG storage facility. Let's start

specific emergency mitigation measures for specific types of emergencies, as

noted above.

Pre-fire plan

The pre-fire plan or pre-incident plan

is prepared to effectively mitigate any emergency to minimize the losses.

Generally, the pre-fire plan is developed by emergency responders

such as fire and rescue services. NFPA 1620 provides detailed guidelines for

developing pre-fire plans to assist emergency responders in

effectively mitigating emergencies. When developing the pre-fire plan,

it is necessary to ensure the protection of plant peoples, emergency response

personnel, property and the environment.

|

| Pre-fire plan for LPG sphere emergency |

The pre-fire plan must be prepared for a

specific machine / equipment / sphere/ vessel or structure in a specific installation

in refinery or oil terminal with reference to the QRA. It must be documented

and guarantee its accessibility to all emergency responders. It can be

communicated at the facility level for better understanding and to reduce the

response time of emergency responders.

Below important points must be considered in the pre fire plan document.

Data collection: QRA report and list of

credible scenarios for specific equipment.

Scope: When preparing the pre-fire

plan, the physical site condition must be taken into account.

Procedure and Templates: The

procedure for developing a pre-fire plan with a standard template

must be finalized for standardization.

Human occupation: When preparing the pre-fire

plan, the density and type of occupation and the level of exposure to a

particular equipment / area must be taken into account.

Fire protection system: During

the preparation of the pre-fire plan, collect all data to know

the availability of existing water supply and fire protection systems

Hazard Consideration: List all

possible hazards and communicate to the responders and mitigation team,

including special hazards.

Emergency management action plan and strategy:

finalize emergency operations, fire-fighting tactics, dilution and dispersion

tactics of toxic gases / flammable gases.

Resources requirement:

Estimated resources including manpower, firefighting equipment, firefighting

media, etc

Welfare and medical facility:

Estimated welfare facility must be considered while preparing pre-fire plan for

major emergencies. It must also include ambulance and other emergency

transportation facility and first Aid.

Fire drill / Mock drill: Pre-incident

plan must be practiced by conducting regular fire drills/ mock drill. It should

be dynamic document and should be reviewed and revised with changes in

technology and for new hazard identification.

Pre-fire plan for management of LPG leakage, UVCE and to prevent BLEVE

Ref. Quantitative Risk Assessment (QRA) of

the LPG storage spheres, the risk

level should be considered while preparing the pre-fire plan and

developing an emergency response plan.

The

pre-fire plan can be prepared by the fire

department in consultation with the operations team. Pre-fire plan should

be prepared for all credible scenarios. Here for understanding, we are

considering below major scenarios having maximum impacts.

TITLE

Vapour cloud explosion and risk

of BLEVE due to LPG leakage from downstream flange of LPG spheres body valve at

Storage, Sales, Dispatch Area (SSDA)”

CREDIBLE

EMERGENCY SCENARIO

Leakage of LPG in liquid phase

from downstream flange of MOV due to Gasket failure (Considered - Sphere body

valve is not in position to be closed manually & ROV not working)

Vapour cloud has formed and

covered about 1 km area.

UCVCE occurred due to unknown

source.

Fire at flange with jet flame

impingement on the adjacent LPG sphere.

Prolong Flange impingement on

Sphere shows sign of BLEVE

Three LPG spheres present in one

group of layout

Wind speed is about 24 km/hr

EQUIPMENT

DESCRIPTION

Diameter of LPG Sphere = 17m.

LPG is received from storage area

and stored in SSDA LPG sphere and dispatched to LPG gantry for wagon filling.

Capacity = 2573 M3

PRODUCT

DATA

Material Name : LPG

Operating Temperature : 25 deg C

Operating Pressure : 8 to 9 kg/cm2

LEL : 1.9 %

UEL : 9.5 %

TLV : Butane : 800 ppm Propane : 1000 ppm

Normal Boiling Point : -40 deg C

Auto-ignition Temperature : 432 deg C

Vapour Density : 1.5-1.8 gm/cc

Specific Gravity : 0.51 – 0.58

Water Solubility : Slight, 6.1% by volume

Operating Temperature : 25 deg C

Operating Pressure : 8 to 9 kg/cm2

LEL : 1.9 %

UEL : 9.5 %

TLV : Butane : 800 ppm Propane : 1000 ppm

Normal Boiling Point : -40 deg C

Auto-ignition Temperature : 432 deg C

Vapour Density : 1.5-1.8 gm/cc

Specific Gravity : 0.51 – 0.58

Water Solubility : Slight, 6.1% by volume

CONSEQUENCE

BLEVE: - If the fire not controlled & insufficient cooling

operation may lead to BLEVE

Damage Distance (685 m)

@ 37.5 kW/m²

Damage Distance (1180 m)

@ 12.5 kW/m²

Damage Distance (1978 m)

@ 4.0 kW/m²

Explosion shock waves can damage the Life & property

within 2 KM range.

Adjacent LPG spheres (3

No) may cause secondary BLEVE.

|

| Consequences analysis for LPG sphere emergencies |

May cause multiple fires at SSDA storage area and

installations in facility.

Massive damage to Health may occur

Impact of Incident may affect nearby community.

COMMUNICATION

MODE

06 nos Manual Call Point (02 at North , 01 at west, 01 at

south & 02 at east side)

LPG Detectors – 4 Nos

FIRE

PROTECTION SYSTEMS

The sphere is protected with water spray deluge system.

Fire water hydrant network is provided all around the dyke

Fire water monitors around the side of the dyke – 8 Nos

Portable DCP extinguishers are available in the dyke &

near the LPG compressor.

Vapour balancing line is provided with All LPG spheres to

prevent BLEVE.

(Note: When preparing the pre-fire plan, the total

number of fire protection systems must be taken into account with their

identification / tagging.)

·

Fire Hydrants = ___Nos and location

·

HVLRM (2000 GPM) = ___Nos and location

·

Water cum foam monitors = ___Nos and location

·

Water spray systems (DV) = ___Nos and location

·

Water spray systems (manual MVWS) = ___Nos and

location

·

Manual Call points = ___Nos and location

·

Fire & Gas detectors= ____Nos and location and

location

·

Fire Extinguishers = ___Nos and location

·

Foam Trolley = ___Nos and location

·

Hose Box = ___Nos and location

FIREFIGHTING

STRATEGY

Suspend all the jobs (hot/ Cold) and evacuate the area

immediately within 2 KM range.

Operate MVWS system for LPG sphere shell cooling for both

affected sphere & adjacent spheres to protect from radiation heat.

Isolate all LPG spheres & stop all operation of LPG

transfer.

Start water monitors in spray mode.

Transfer of LPG to other safe sphere after thoroughly

understanding the situation Contact Mutual Aid for backup and to evacuate

nearby community & barricading the nearby highways within the range of

about 2 KM radius.

A large leakage of the LPG can form a

vapour cloud that can travel up to 1.9 Km.

Approach the fire or gas leakage area from

upwind or crosswind. All ignition sources down wind of leak should be put off

or water curtain should be provided immediately.

Evacuate the area within the range of

vapour clouds as quickly as possible. In case, escaping LPG is not on fire,

activate the ROV to cut off the source of LPG. Water spray is effective in

dispersing LPG vapours. The spray stream should be directed across the normal

vapour path.

Do not attempt to extinguish the LPG

fire unless the source of the leak cut off. A small LPG fire can be

extinguished by Dry chemical powder. The extinguishing agent should be directed

to the point of vapour release. Immediately start water spray on the leaking

LPG to avoid re-ignition.

The best method is controlled burning of

leaking LPG as it prevents the formation of vapour cloud. The application of sufficient

quantity of water to keep the shell of the vessel and piping cool will allow

the fire to consume the products without risk of causing failure. It is

desirable that the leaks cannot be controlled after extinguishing fire and

wherever the leak can be controlled, attempt to extinguish the fire.

Firefighting strategy for LPG storage sphere

fire

Do not extinguish the flame except by

elimination of fuel, as the accumulation of leaking gas forms a flammable

vapour cloud and increases the risk of explosion due to accidental ignition.

Stop the movement of the product in

and out of the tank by activating ROVs, etc.

Use the water spray system to cool the

shell of LPG sphere, if this seems ineffective, use ground water monitors to

cool the vessels. Do not apply a solid jet directly on the shell of the LPG

sphere. Always make sure that water application must be in spray mode.

In the event of a fire in the bottom

section, apply water spray through fixed/mobile water monitors to the piping

assembly/supporting structure. Water cooling should be carried out on the

adjacent storage vessels.

Water cooling on the affected vessel

should be continued even after the flame has been extinguished until all danger

of re-ignition of the hot surfaces or other sources has been eliminated.

Water spray protection for fire

fighters should be provided continuously as long as the danger of vapour cloud

persists.

If possible, pump water into the

vessel to float the flammable material above the leak point in the vessel/sphere.

This will extinguish the flames if the rate of water pumping exceeds the rate

of leakage (an attempt should only be made when competent to do so).

If a shell failure occurs below the

liquid level in the vessel/sphere and results in a leak that exceeds the

capacity of the water pumping facility, several solid streams of water should

be directed on the shell surrounding the leak.

Try to form a curtain of water spray

and maintain it until all flammable material i.e. LPG has been consumed and the

vessel has become gas-free by natural ventilation or by the addition of steam in

the vapour space of the sphere/vessel.

Before resuming the plant operations

after the end of firefighting, a gas test should be carried out in pits,

trenches or dykes where gas or heavy vapours could accumulate. Portable gas

detectors should be used to check for the presence of flammable gas. Similar

precautions and firefighting operation must be followed in the event of fire in

the LPG recovery Unit.

RESOURCE

ESTIMATION

Firefighting resources:

Fire water requirement for affected sphere cooling = 556 m3/hr

Fire water requirement for adjacent two sphere cooling = 1112

m3/hr

Fire water requirement for hose stream and one monitor = 375

m3/hr

Fire water requirement for fixed ground water monitor (4Nos) =

912 m3/hr

Total fire water Requirement = 2955 m3/hr

Personal protective equipment and lifesaving equipment

SCBA set = 14 Nos with 100% spare cylinders

Cryogenic suit and hand gloves = 20 Nos

Red flag for vapour cloud marking = 12 Nos

Firefighting suit = 14 Nos

Manpower resources

Fire officer – 02 Nos

Firefighters = 14 Nos

Auxiliary fire squad for replacement of front line responders

= 14 Nos

First Aiders = 3 Nos

Doctor at medical center = 01 No

Firefighting equipment, appliances and medical transportation

Fire engine =2 Nos

DCP fire engine = 1 No

Fire hoses = 40 Nos (15m length each)

TP branches/ nozzles = 6 Nos

Dividing breaching = 4 Nos

Water curtain = 4 Nos

Ambulance = 2 Nos

Portable gas monitor = 3 Nos

Welfare facility

Transportation for manpower replacement = 2 Nos

Dehydration remedy kits = 4 per person

Drinking water at site = 2 ltrs per person

EMERGENCY

RESPONSE

Emergency Team

Field officer

Actuate the nearby MCP,

inform to operation panel officer and shift incharge via Walkie Talkie.

Operate Deluge system of LPG spheres.

Stop the transfer/ receive of LPG.

Stop all nearby jobs immediately.

Assist the firefighting team.

Company Incident Controller

Report to site and take charge of incident site as per

Emergency management and response plan.

Assess the site & coordinate with DCS panel officer for

mitigation.

Direct all emergency operations as per SOP.

Coordinate with all emergency team members i.e. Fire/

Security/ Medical/ etc

Ensure personnel are moved to the Master assembly point

outside the range of about 2 KM radius.

Stop Loading/ Unloading operation of Truck & rail gantry.

Update the company head for probability of BLEVE &

consequences thereof.

Evacuate all manpower including Emergency control team &

equipments at any sign of BLEVE to occur.

Determine level of emergency & inform to Site main

Controller (SMC).

Seek additional support and resources for controlling the

emergency & evacuation of nearby community. Suggest SMC to Actuate Offsite

emergency plan with district disaster control center and mutual aid.

At end of an emergency, assess damage & environmental /

toxicity level, declare ALL CLEAR.

Firefighting team

After receiving an emergency call, the fire team must present

themselves urgently with all appropriate firefighting equipment, personal

protective equipment and report to the emergency site.

While taking emergency turnout from the fire station, make

sure of the wind direction, be in constant contact with the fire control room.

After reaching the emergency site, the fire tender / fire engines should only

be parked in the upwind / crosswind direction. The fire tender must be parked

in a safe place and directed towards the exit.

Evaluate the scenario, get all the information about the emergency

site from the plant shift in-charge or site incident controller and a brief

final mitigation action to all firefighters.

All members of the fire crew must wear self-contained

breathing apparatus (SCBA). Two firefighters must ensure the connection of the

hydrant to the Fire tender for make-up water and be ready for firefighting.

The rescue operation must be launched at the initial level by

two firefighters and the other firefighters must be ready for the dispersion of

gas and firefighting.

If necessary, call in for additional fire assistance and

resources. If possible, cool nearby equipment using the deluge water spray (DV)

system.

The fire commander should assess the situation and ask the

firefighting team to use a fire suit / heat resistant suit / other specialized

equipment.

Operate the groundwater monitor / tower monitor and HVLRM (high-volume long-range monitor)

for water.

Help the operations and maintenance team to mitigate the

incident. If there is a demand to close the process isolation valve which is

engulf in fire, the responder must wear a fire entry suit with a water spray

back-up line. These water spray must continue to provide a cooling effect to

the personnel involved in closing the isolation valve.

Water curtain must be provided to isolate the radiant heat, if

possible. Intensive cooling of the surrounding installations must be ensured to

prevent the spread of fire.

The fire chief must ensure the required fire water header pressure

of the fire water system in coordination with the operator of the fire water

pump house. If situation demand, the fire chief may consult the site incident

controller for any further assistance from mutual aid members, the auxiliary

team, etc.

All actions to mitigate the incident must be carried out under

the instructions of the fire chief. Check the LEL with the operating team in

consultation with the site incident controller.

Ensure adequate drainage of spills and take the necessary

measures to eliminate any contaminated surface.

After ALL CLEAR, stop the operation of fire protection system

and communicate the fire water pump house about no further demand. Ensure the

restoration of all emergency fire equipment / appliances.

Security team

Reach at Site & report to CIC.

Controls access to the Incident site

Allow smooth entry of external emergency team as per ERMP and

through predicated entry gate.

Control traffic and personnel movement by ensuring proper

barricading the area/ Road within 2 KM.

Assist Rescue & Fire Fighting operation.

Security Personnel’s to be available at various locations to

guide the Outside Emergency vehicles to site.

Medical team

Ambulance should be reported at emergency site.

Mobilize injured persons from the site to health center

First Aid to be administered.

Mobilize second Ambulances (if required).

Mutual Aid Team

Police: - Barricade the Highway & control the traffic

Fire Brigade – entry shall be as per ERMP

District Authority: - Arrange for extra resources and evacuate

nearby community

EMERGENCY

CONTACT & COMMUNICATION SYSTEM

Emergency No of fire

control room: XXXXXXXX

DHDT panel contact No:

XXXXXXXX

******* End******

Above

is the one example of pre-fire plan for LPG

storage sphere fire for specific scenario. Similarly, pre-fire plan must

be prepared separately for each credible scenario with ref to QRA study.

Pre-fire

plan template

Here is

the standard template and sample pre-fire plan developed

according to our experience. This template can be revised depending on the site condition. Standard NFPA 1620, latest edition 2020 can be referenced for a pre-incident

template, but it is mainly applicable for building and may not be

suitable for a refinery.

Click

here to download

Standard template for Pre-fire plan for

oil Refinery credible scenarios

Sample pre-fire plan for LPG sphere

emergency

Conclusion

LPG storage and handling facility is extremely prone to major

accidents, including fires and explosions due to its inherent flammability

property. Preparation of Pre fire plan or Pre incident plan

for specific equipment in specific operational area is the key for effective

mitigation of any emergencies. Quantitative Risk assessment must be referred

while preparing the pre fire plan. Effective emergency

response can be assured by regular practicing i.e. conducting fire

drill based on pre-fire plan. Practical firefighting

strategies must be included in pre fire plan for all emergencies,

including fires, explosions and the release of toxic gases. Important information

such as process

description, material data, list of hazards substances with their properties, list

of available fire protection system, layout, approach rout marking on layout,

line of action and firefighting strategies, estimated resources etc must be the

part of pre fire plan.

I read a lot of stuff and i found that the way of writing to clearifing that exactly want to say was very good so i am impressed and ilike

ReplyDeleteto come again in future.. I'm no expert, but I believe you just made an excellent point. You certainly fully understand what youre speaking about, and

I can truly get behind that. best fire extinguisher

If you have never had a fire pit before and you are thinking of gas as a fuel source then this article is for you. If you have had a wood burning fire pit and local authority regulations have decreed that you cannot use it or you are looking for the convenience of gas then this article is for you. This article is intended to compare Propane (LPG) versus Methane (NG) as a fuel source for fire pits. The choice of fuel influences Matthew Fleeger

ReplyDeleteVancouver fire safety plans Very efficiently written information. It will be beneficial to anybody who utilizes it, including me. Keep up the good work. For sure i will check out more posts. This site seems to get a good amount of visitors.

ReplyDelete