Layer of protection Analysis - LOPA - HSE guide

Layer of protection Analysis - LOPA

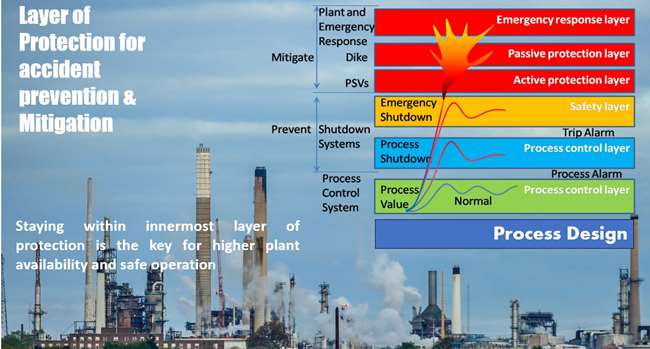

There

are seven layers of protection for accident prevention and

mitigation. Each layer is important as some are for prevention and other are

for protections. Staying within inner most layer of protection is

the key for higher plant availability and safe operation. Maintaining other

layers of protection intact, ensure prevention and mitigation of accidents.

In

this article we will discuss what LOPA is and how it is carried out step

by step.

The

Layer of protection analysis (LOPA) is a risk assessment tool

developed within the framework of an international standard to quantify risks

in order to reach a specific probability objective. It is a systematic

decision-making process and one of the methods for determining the risk

associated with various hazardous process events using their severity and the

probability of the events occurring.

Applicability of LOPA

LOPA is

generally used for high-risk scenarios where the quality of the decision must

be higher and allows a multidisciplinary team to assess the risk with greater

clarity and more explicit decision criteria. It is used to ensure that a design

is not under-designed, that the design is not over-designed, that people are

not exposed to excessive risk, to verify that operating resources are adequate,

don't waste money, etc. Thus, LOPA is concerns about allocating

appropriate resources proportional to the risk.

Concept of risk acceptance / tolerance in the LOPA

Before

starting the layer of protection analysis (LOPA), the company

must define the tolerable frequencies for events with high consequences.

The

LOPA is used to assess a specific scenario to determine whether it is

acceptable, depending on the consequence, risk tolerance may differ from one

person to another. Therefore, when analyzing the layer of protection, the

challenge is to have a team of experienced people with diverse backgrounds and

objectives to make rational business decisions (a rational business decision is

a decision that makes sense for long-term business).

Sometimes

a decision may make sense for the life of the project but will expose an

installation to undue risk or it is on the way. The level of risk acceptance is

expressed in terms of tolerable frequency which is the maximum number of events

expected per year, which is considered practicable, achievable, sometimes this

can be expressed in terms of probability. The tolerable frequency is the

decision criterion for design and operational changes. It is a risk tolerance

objective set by a company and often aligned with society's expectations to

make consistent decisions. The justification is simple, the more the

consequence decreases the tolerable frequency. As a general rule, the industry

accepts a 0.01% chance of a single death in a given year, i.e. the risk of

death is 1 in 10,000 for an individual per year. It would expect several deaths/

multiple fatality to be less tolerated with a tolerable frequency of 0.001%

chance per year. More serious is the consequence of lowering the tolerable

frequency.

Decide

on the level of risk tolerance in the business to set the business goals. The

operator can set the target by focusing on quarterly production targets, the

project manager focuses on lead times and the tolerable frequency should be set

at the company level while the risk is perceived at the portfolio level.

Concept of conducting a layer of protection analysis

The

LOPA begins by focusing on a single consequence and applies to the higher

severity scenarios identified in the HAZOP.

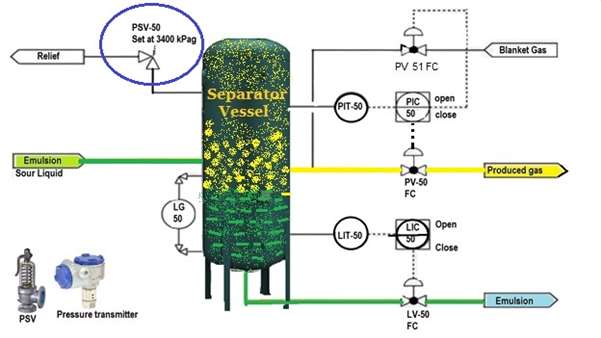

We

will take the help of the schematic diagram below to understand the concept

layer of protective;

|

| Fig-1 - Schematic diagram of separator vessel with pressure valve at gas outlet |

Suppose,

in an example above, consider a separator vessel over pressurizing, the worst

credible case of a vessel rupture results in the death of a single worker

nearby. Now, we must apply the tolerable frequency of the over pressure of the

separator vessel which can cause death according to the standards defined by

the company. Then think about, how can a company reasonably tolerate it, how

can an engineer demonstrate that the design is as low as reasonably practicable

(ALRAP). From now on, designing this process according to the consequence of

the death of a single worker can occur at most at 0.01% per year.

At

this point, we now need to determine what triggered the consequence and the

likelihood of it happening. We must send back the HAZOP, the cause of a

deviation in an HAZOP is the initiating event in the protective layer. If we

see in our study example, the triggering event is the faulty pressure control

valve in the closed position. There is a blocked flow from the gas line

produced when the PV-50 is closed, causing the vessel to over pressure. let's

say that the pressure control valve has a probability of 0.1 of failing to close

in a year or in other words, the expected inadvertent closure is once every ten

years.

Now

the next step is to identify the independent protective layers in the system,

these are mechanisms that prevent the consequences from occurring. These

independent layers of protection are the safeguards identified during a HAZOP

to assign a backup. As an independent protective layer, it must meet specific

requirements defined by international and regional standards. It is important

to remember that the protective layer must be independent of the triggering

event and of the other safeguards applied to this scenario. Here, the team of

experts must decide which independent protective layers can be used. We can

therefore consider here that the Pressure Safety Valve (PSV) on the separator

vessel can be provided,

|

| Fig-2 - Pressure safety valve |

Let’s

take the PSV-50 which will protect the separator vessel from excessive

pressure. In addition, it is clearly independent and there would be no impact

from the PV failure. This can certainly reduce the probability of a vessel

rupture by a factor of 10, it can also be expressed as a risk reduction factor

of 10 or a probability of failure on demand of 0.1.

Now

is the time to calculate the expected frequency of the consequence. Here we

need to determine the probability of the triggering event, i.e. the pressure

control valve inadvertently closes and the probability of PSV-51 failure and

the probability of the vessel rupture. The expected frequency can be calculated

taking into account the fact that the vessel is in an area with heavy traffic

and that a person is present when a vessel rupture. Consider 1% chance of death

per year, or 1 in 100 chance.

Now

decide whether the risk is tolerable or not. If the risk is acceptable based on

the tolerable frequency, make a risk-based decision, is this process as safe as

we want it to compare what we calculated and the tolerable frequency this

scenario is 100 times more likely to happen than is acceptable. Since we cannot

accept this risk, we must find a way to further reduce the risk.

Here

we must determine the additional safeguard to reduce the risk of respecting the

tolerable frequency. We can add an independent high-pressure shutdown on the vessel

blanket gas as collateral to eliminate the high pressure source.

|

| Fig-3- Provision of SIF |

We

can add a backup safeguard that consists of a sensor, logic solver and a valve

called as Safety Instrumented Function (SIF). It is an automated safety action

to bring the process to a safe state. The current system is 100 times more

likely than acceptable. The Safety Instrumented Function (SIF) must reduce the

probability by a factor of 100. The reliability target of this function must

have a probability of failure on demand (PFD) of less than 1%. As this safety

function must reduce the consequence, probably by 100 times, it must meet the

requirements of safety integrity level 2 (SIL-2).

|

| Fig-4-Provision of safety instrument system with SIL level calculation |

Here, the

combination of the sensor, logic solver and the final element meets the

requirements of safety integrity level 2. Now we can calculate the new expected

frequency of the system, as below;

With

safeguard, expected frequency = 0.1 (PFD of Valve) x 0.1 (PFD of safety valve)

x 0.01 (PFD of SIF)

=

0.0001/year

= 0.01 %

per year

Here, the

final result is 0.01% chance per year. So finally, we can conclude that the

likelihood of the vessel over pressurization is within tolerable frequency and

risk is acceptable.

Conclusion

The

layer of protection analysis (LOPA) is a risk assessment tool which

is used for a systematic decision-making process and one of the methods for

determining the risk associated with various hazardous process events using

their severity and the probability of the events occurring. By evaluating the process

failure causes in reference to HAZOP, a team of expert deciding the best

control to minimize the risk at tolerable level. It is step by step process

where independent safeguard are identified and risk level is compared with

company set target for tolerable of risk. Provision of Safety instrument

system with safety instrumented level may reduce the risk at tolerable level.

Related Articles

its nice and very good information, HOW PFD value decided

ReplyDeleteThanks for appreciation

ReplyDelete