How to measure performance of Process Safety Management

To assure continual improvement of any management

system, identification of its strength and weakness in the form of some

measurement is very crucial. Finding the perfect performance measure of Process

Safety is a difficult task. Measurement is just like health checkup and an

important part of Process Safety Management to forms the basis for continual

improvement.

How to measure performance of Process Safety Management

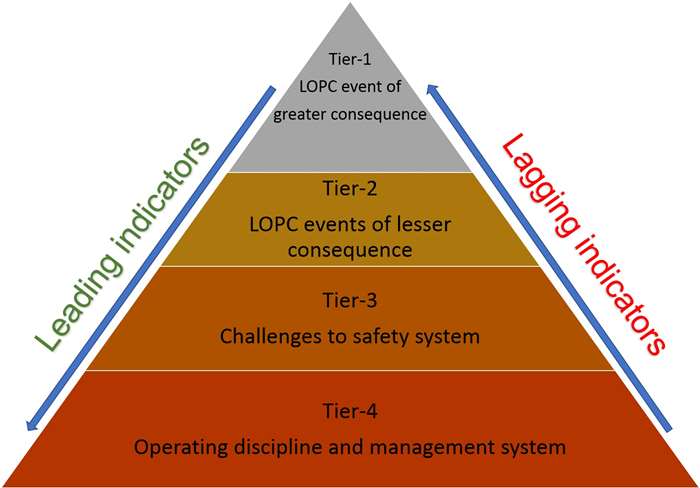

Leading and Lagging are the two types of

measurement used to measure the process safety performance, one indicates the proactive

effort to prevent unacceptable events whereas other identifies the reactive/ lack

of effective management system indicators.

To judge, how well facility is doing at preventing

accidents and incidents and how effectively planning to avoid recurrence of failure,

combination of lagging and leading indicators of safety performance should be

used.

Process safety leading and lagging indicators

" Process Leading Indicator" Metrics: A forward looking set of metrics which indicate

the performance of the key work processes, operating discipline, or layers of

protection that prevent incidents.

"Process Lagging Indicator" Metrics: A retrospective set of metrics that are based on

incidents that meet the threshold of severity that should be reported as part

of the industry-wide Process Safety Metric.

"Process Near Miss" and other Internal process

Lagging Metrics: Unsafe conditions

which activate one or more layers of protection or other less severe incidents

(i.e., below the threshold for inclusion in the industry lagging metric), with

potential to harm either personal, asset or neighboring community & environment.

Leading indicators

1. Asset Integrity:

This metric is one measure of the effectiveness of the

Process Safety Management System to ensure that the Safety Critical Plant and Equipment

is functional.

Number

of Inspections of Safety Critical Items Completed on Time x 100 (in %)

Total Number of Inspections of

Safety Critical Items due

- It includes total Safety Critical Equipment of all disciplines which are due for inspection in the current month.

- Each discipline should have a list of critical equipment based on its criticality for safety, developed using a metrics based on severity and potential consequences. Responsibility of identifying and monitoring progress of each Safety Critical Equipment / item lies with respective department/process head.

2. Action Items Follow-up:

- Includes total safety action points arising out of various safety initiatives viz. PHA, HAZOP, PSSR, Process safety audits & inspections etc.

- There must be a tracking system to ensure that all action points arising out of the various categories listed are captured and are monitored for progress/ completion.

- Responsibility of identifying and monitoring progress of each action item lies with respective department/process head.

3. Management of Change (MOC) effectiveness:

This metric includes only percentage of audited

MOCs that satisfied all aspects of the site's MOC procedure and measures how closely

the site's MOC procedure is being followed.

- It involves a periodic audit of completed MOC documentation.

- A detailed MOC procedure must be in place which describes how MOCS are to be handled from initiation to close-out. MOCS procedure should address changes to equipment, facilities, operating parameters, raw materials, organization structure etc.

- The procedure should also describe the roles and responsibilities of the various departments / end users / service providers for ensuring that the activities described in the procedure are complied.

To know more on MOC, Click here

4. Process Safety Training:

Focus should be on Process Safety Training

provided to company employees. This will include training carried out on topics

viz. PHA, HAZOP, PSSR, MOC, FMEA, ETA, FTA, SIS, QRA, any other relevant topics

etc.

5. Process Safety Audits & Inspections:

Includes only Process Safety Audits and Technical

Inspections viz. audits carried out to ensure updating of PSI, compliance to

Process Safety Procedures viz. MỐC, PSSR, Asset Integrity, Trip/Interlock

By-pass, SOPS etc.

6. Process Safety Incident Investigations:

Includes all Process Safety Incidents as well as

equipment failures leading to unit/ plant trip/ shutdown. Any type of Leak,

Smoke & Fire is counted as a Process Safety Incident.

7. Bad Actors resolved:

Includes all faulty/ erratic/ part functional/

non-functional equipment and/ or accessories reported during the month that

hamper proper process operation as per intended design.

Lagging Indicators

1. Total Process Safety Incident Count:

For the purpose of the common industry-wide

Process Safety Lagging Metrics, an incident shall be reported as a Process Safety

Incident, if it meets all four of the following

criteria:

- Chemical or chemical process involvement

- Above minimum reporting threshold

- Location

- Acute release

A release of material or energy from a chemical

process, which results in any of the three situations below:

- An employee or contractor Lost Time Injury and/or fatality, or hospital admission and/or fatality of a third party (non-employees/ contractor).

- Fires or explosions resulting in greater than or equal to $25,000 as direct cost to the company.

- An acute release of flammable, combustible, or toxic chemicals from the primary containment (i.e. vessel or pipe) greater than the Chemical Release Threshold Quantities, excluding releases to properly designed and operating control device specifically designed for that event (e.g., flare scrubber or relief devices as per API Standard 521)

2. Process Safety Incident Frequency Rate:

Total PS incidents X

20,000

Total employees and contractor man

hours

3. Trips / Interlocks bypassed: Number of Trips/ Interlocks Bypassed in the month

4. Fire / Safety equipment non-functional: Number of Fire/

Safety Equipment which are unavailable or non-functional in the month.

5. Bad actors unresolved: Number of bad actors unresolved in the month

6. Safety / Relief valves or Rupture discs

isolated/ blinded: Number of safety valves

or rupture discs isolated/ blinded in the month.

7. Unit / Plant trips and shutdowns: Number of Unit / Plant Trips and Shutdowns in the

month due to equipment failure in the month.

Conclusion

Combination of leading and lagging indicators must

be used to improve the performance of process safety. When using leading

indicators, it is very important to make the PSM matrix based on impact. E.g.

Number of training carried on different topics are less important than its

validation because validation is the only indicator to know how much understood

by participants.

Related Articles

Process Safety Management

Reporting of process safety incidents and near-misses

Safe mechanical completion, Pre-commissioning, Commissioning, startup of Oil Facility

Process Safety Management

Reporting of process safety incidents and near-misses

Safe mechanical completion, Pre-commissioning, Commissioning, startup of Oil Facility

nice

ReplyDeleteWell noted

ReplyDelete