Process Safety Management (PSM) | 14 Elements of PSM

Process Safety Management (PSM)

Here we are trying to understand the basic definition

of “Process Safety Management (PSM)”, requirement in hazardous industries and its

element for better implementation of systems.

The various lines of

defense included in the design and operation of the process to prevent or

reduce the release of hazardous chemicals must be evaluated and strengthened to

ensure their effectiveness at all levels. Process safety is proactive and centers on the

Safety Integrity of the process.

Definition of Process Safety Management

"Process Safety Management is the proactive

identification, evaluation and prevention of chemical releases that could occur

as a result of failures in process, procedures, or equipment"-OHSA.

Process safety for the most part

alludes to the anticipation of unwanted releases of chemicals, energy or other

conceivably dangerous materials during process that can seriously affect the

plant and nature.

After series of serious accidents (like Bhopal gas

Tragedy & Piper alpha, North Sea) that occurred in 1980's, OSHA

(Occupational Safety and Health Administration) developed Process Safety

Management rules in 1992. These rules made mandatory in USA for Chemicals handling,

storing/processing above a threshold value. Elements under PSM rule set the

requirement for management of hazards associated with processes using highly hazardous chemicals.

Scope of Process Safety Management

Process Safety Management is applicable in a

process which involves a chemical at or above the specified Threshold

Quantities (TQ) listed in annexure of the Rule 29 CFR 1910.252 (a); or A process that

involves a flammable liquid or gas at the site at a location, in an amount of

10,000 pounds (4,535.9 kg) or more..

Elements of Process Safety Management

For better understanding, all elements of Process

Safety Management can be divided in different group.

Group-1: Knowledge and operational control

- Process safety information

- Operating procedures

- Hot work permit and other Safe work practices

- Contractors management

- Training

Group-2: Hazard identification and controls

- Process hazard analysis

- Management of change

- Pre-startup safety review

- Mechanical integrity

Group-3: Incident learning and response

- Incident investigation

- Emergency planning and response

Group-4: Participation and Management

- Employee participation

- Compliance audit

- Trade secretes

Knowledge and operational control

1. Process Safety Information

The purpose of Process Safety

Information (PSI) is to bring awareness to all employees, workers and their

representatives involved in process operation to identify and understand the hazards

posed by those processes involving hazardous chemicals by sharing information on process

technology, process equipment and chemical

hazards.

MSDS can

be used as source for getting chemical information ie. toxicity, TLV, physical

data, reactivity, etc. whereas information on process technology can be get

from process flow diagram, process chemistry, safe limits of process parameters,

etc. Information on equipment can be collected from its manufacturer data sheet,

P&IDs and other engineering designs.

2. Operating Procedures

The purpose of operating procedures is to provide

clear instructions for performing particular process activities safely in consistent

with the Process Safety.

The operating procedures shall be developed for

each of the operating phases and must address below elements;

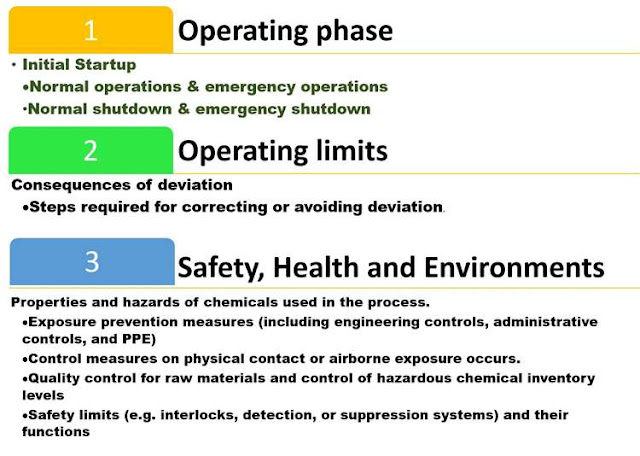

Operating phase:

- Initial Startup

- Normal operations & emergency operations

- Normal shutdown & emergency shutdown

Operating limits:

- Consequences of deviation

- Steps required for correcting or avoiding deviation.

Safety, Health and Environments:

- Properties and hazards of chemicals used in the process.

- Exposure prevention measures (including engineering controls, administrative controls, and PPE)

- Control measures on physical contact or airborne exposure occurs.

- Quality control of raw materials and control of levels of stocks of hazardous chemicals.

- Safety limits (e.g., interlocks, detection, or suppression systems) and their functions

3. Hot work permit and other safe work practices

Working in hydrocarbon processing or/and handling installations

presents special risk and in order to provide safe working conditions and to

carry out the special work in restricted area safely, a Work Permit System

shall be followed. The basic purpose of the Work Permit System is to ensure

that work is carried out in the safest possible manner to prevent injuries to

personnel and protect property damage by avoiding fire, explosion, or release

of toxic chemicals.

The employer issues a

permit for hot work activities that are performed in or near a covered process. The permit must

document the fire prevention and protection requirements prior to beginning the

hot work operations. It shall indicate the date authorized for hot work; and

identify the object on which hot work is to be performed. The permit must be retained

until completion of the hot work.

4. Contractors Management

This element applies to contractors who perform maintenance or repair

work, major renovations or specialized work in or in addition to a covered

process, and not to contractors who provide auxiliary services, such as

concierge, catering, laundry, delivery or other services, procurement services.

Employer Responsibilities:

- For selecting the contractor, obtain and evaluate his safety performance.

- Inform contractual employers about the known potential risks of fire, explosion or toxic substances related to the work and process of the contractor.

- Explain On -Site Emergency Plan.

- Develop and implement safe work practices consistent with his activities.

- Periodically evaluate the performance of contract employers.

Contract Employer Responsibilities:

- Assure his employees are trained in the relevant work practices and made aware on potential fire, explosion, or toxic release hazards and emergency action plan. Training record must be maintained.

- Create a file with the identity of the contractual employee, the date of the training and the means used to verify if the employee has fully understood the training.

- Inform any unique hazards presented at his workplace.

Read more on contractor management

5. Training

All employees before being involved in operating a

process must be trained in an overview of the process and in its operating

procedures to manage the process safely and efficiently. Employer may certify

in writing that the employees have the required competency to safely carry out

the duties and responsibilities.

Update courses should be given at least every three years, or more

frequently if necessary, to each employee involved in the implementation of a

process, to ensure that the employee understands and complies with the current

operational procedures of the process. The training file must be maintained.

Hazard identification and control

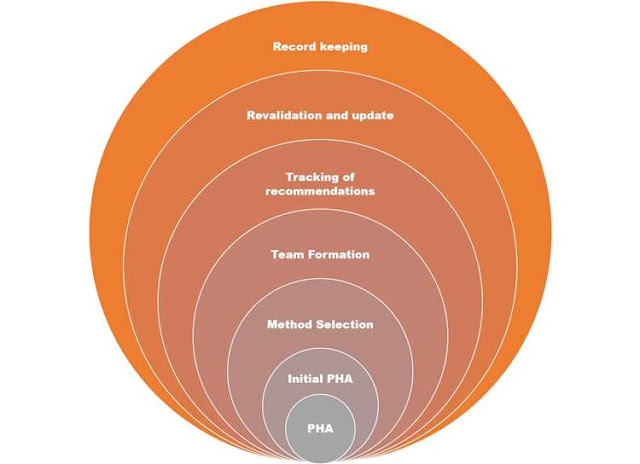

6. Process Hazard Analysis

The purpose of Process Hazard Analysis (PHA) is to

minimize the likelihood of the occurrences and consequences of a dangerous

substance release by identifying, evaluating, and controlling the events that

could lead to the release. It provides information that helps you make decisions to improve safety

and reduce the effects of unwanted or unplanned emissions of hazardous

chemicals.

Initial Process Hazard Analysis: The employer must perform an initial Process

Hazard Analysis (hazard evaluation) on all processes covered by this standard.

Selection of the methodology: The Process Hazard Analysis methodology selected

must be appropriate to the complexity of the process and must identify, evaluate.

and control the hazards involved in the process. The employer must, as the case may be, use one or more of the following

methods to determine and assess the hazards of the analyzed process.

Factors to be included in the PHA: Whichever method(s) are used, the PHA must address the following:

- The hazards of the process.

- Consideration of previous incident that had a potential for catastrophic consequences in the workplace.

- Technical and administrative controls that apply to hazards and their interrelations, such as the correct application of detection methods to provide early emission alerts. (Acceptable detection methods may include monitoring and process control instruments with alarms and detection equipment such as oil sensors).

- Consequences of the failure of technical and administrative controls.

- Facility location.

- Human factors and a qualitative evaluation of a range of possible effects on the safety and health of employees in the workplace in case of failure of controls.

Team Formation for Process Hazard Analysis: The PHA must be

performed by a team with experience in engineering and process operations, and

this team must include at least one employee who has experience and knowledge

of the process to be evaluated. In addition, a team member must know the

specific analysis methods.

Establishment of Recommendation Tracking System: The employer must establish a system to address

promptly the team's findings and recommendations; assure that the

recommendations are resolved in a timely manner and documented. Develop a

written schedule of when these actions are to be completed; complete actions as

soon as possible; and communicate the actions to operating, maintenance, and

other employees whom work is assigned and who may be affected by the

recommendations or actions.

Re-validation and Updating of Process Hazard Analysis: At least every five years after the completion of

the initial process hazard analysis, the hazard analysis shall be updated and

re-validated by a team to assure that the PHA is consistent with the current

process.

Record Keeping: Employers must retain the PHA and any update or extension for any

process found in this section, as well as the documented resolution of the

recommendations.

7. Management of Change

The intent of the Management of Change (MOC) is to

manage modifications to technology, equipment, facilities, processing conditions

or any changes within the documented technology, which are not a replacement in

kind. All plant changes should be identified and reviewed prior to their

implementation and the impact of design; operational and procedural Changes on process

safety should be addressed and controlled.

Written procedure of MOC: The employer must establish and implement written procedures to manage

the changes (with the exception of "in-kind substitutions") to treat

chemicals, technology, equipment and procedures; and changes in the

characteristics that affect a covered process.

Considerations to be addressed prior to any change:

The procedures shall

assure that the following considerations are addressed prior to any change:

- The technical basis for the proposed change

- Impact of change on safety and health

- Modifications to operating procedures

- Necessary time period for the change

- Authorization requirements for the proposed change

Communication and Training: Employees involved in the operation, maintenance and hired employees

whose functions may be affected by a change in the process must receive

training in the change before the start of the process or an affected part of

the process. They must be informed of the scope of the process hazards.

Process safety Information Update: On the off chance

that an adjustment in this segment changes the procedure data, this data ought

to be refreshed likewise

Operating Procedure Update: If a change covered by this section results in a

change in the operating procedures or practices, such procedures or practices shall

be updated accordingly.

8. Pre-Startup Safety Review

The purpose of Pre-Startup Safety Review (PSSR) is

to ensure that new/modified facility is ready for safe and continuous

operation.

The PSSR must confirm the following, prior to the

introduction of highly hazardous chemicals to a process.

- Construction and equipment meet design specifications.

- Safety, operation, maintenance and emergency procedures are present and adequate.

- For new modified facilities, a MOC procedure had been followed, and all HAZOP recommendations have been implemented before startup.

- Training of each employees involved in operating a process has been completed.

9. Mechanical Integrity

The purpose of mechanical integrity is to ensure the

availability of process and components on demand as per the design intent, which

include the following:

- Pressure vessels and storage tanks.

- Piping systems.

- Relief & vent systems and devices.

- Emergency shutdown systems.

- Critical controls (including monitoring devices and

- sensors, alarms, and interlocks); and

- Pumps and Compressors

We must ensure written procedures to maintain the

ongoing integrity of process equipment, training for process maintenance

activities to assure that the employee can perform the job tasks in a safe manner

and inspections shall be performed on process equipment. Inspection and testing

must be done as per set procedure and in consistence applicable manufacture

recommendation and good engineering practices. All inspection and test shall be

well documented.

All the equipment deficiencies that are outside acceptable

limits shall be corrected in a safe timely manner. Ensure that all equipment is

fabricated as per the specification and installed properly in consistent with

design specifications and the manufacturer's instructions. Maintenance

materials, spare parts and equipment should be suitable for intended

application.

Incident Learning and Response

10. Incident investigation

A workplace process incident

is an indication that prevention was ineffective and that prompt changes need

to be made, Therefore, every process incident and Near Miss must be recorded

and thoroughly investigated to prevent recurrence of the incident.

Investigation of

Incidents/Near-Miss Involving highly hazardous chemicals: Each incident shall be investigated which

resulted in or could reasonably have resulted in a catastrophic release of highlyhazardous chemical in the workplace.

Initiation of

Investigation: An incident

investigation shall be initiated as promptly as possible, but not later than 48

hours following the incident.

Formation of Team: An incident investigation team must be established with at least one

person familiar with the process involved, including an employee hired if the

incident concerned the work of the contractor and others with the appropriate

knowledge and experience to thoroughly investigate and investigate the incident.

Content of Investigation

Report: A report shall be prepared

at the conclusion of the investigation which includes at a minimum date of

incident, the date on which the Investigation began, description of the incident,

the factors that contributed to the incident; and any recommendations tracking

from the investigation.

Recommendation racking

System: The employer shall

establish a system to promptly address and resolve the incident report findings

recommendations. Resolutions and corrective actions shall be documented.

Report Review: The report should be evaluated with all relevant personnel whose

functions are relevant to the conclusions of the incident, including employees.

Retention of Reports: Incident investigation reports shall be retained

for five years.

11. Emergency Planning and Response

Most emergencies, such as major fires, explosions, toxic emissions, oil

spills, etc., can be controlled by carefully assessing possible planned events

and developing a plan to deal with such situations, organize exercises or

perform appropriate tests. carry out effective implementation at the time of

the emergency. An emergency action plan (ERP) for the entire facility must

comply with the provisions of 29 CFR 1910.38. In addition, the ERP will include

procedures for dealing with small emissions.

Written and oral

Emergency Action Plans: An EAP

must be in written, kept in the workplace, and available to employees for

review. However, an employer

with a maximum of 10 employees can verbally communicate the plan to employees.

Minimum elements of an

Emergency Action Plan: An ERP

must include at least below;

- Procedures for registering a fire or other emergency:

- Emergency evacuation procedures, including type of evacuation and allocation of exit routes.

- Procedures for Remaining Employees to Perform Critical Factory Operations Before Evacuating

- Procedures for reporting to all employees after evacuation.

- Procedures to be followed by employees performing rescue or medical operations; and

- The name or position of each employee (whom employees can contact) who needs more information about the plan or an justification of their duties under the plan.

Employee Alarm System: Have and maintain an Employee Alarm System (EAS).

The EAS must use a distinctive signal for each purpose and comply with the

legal requirements.

Training: Designate and train employees to assist in a safe

and orderly evacuation of other employees.

Review of Emergency

Action Plan: Review the EAP with

each employee covered by the plan:

- At the point when the arrangement is created, or the worker is at first allotted to a vocation.

- When the employee's obligations under the plan change.

- When the plan is modified.

Participation and Management

12. Employee participation

The purpose of employee participation

is to consult with employees, workers and their representatives on hazard

assessments posed

by those processes involving highly hazardous chemicals by sharing information

on process technology, process equipment and development

of chemical accident prevention plans. It provides the access to these

documents and other records required under the standard.

13. Compliance audit

The purpose of compliance audit is identification

of vulnerable areas and specific potential hazards i.e. one of the prime functions

of loss prevention in process industry. Auditing is an important means for performing this function.

Standard Requirements:

Evaluation of Compliance: Top management must ensure that they have evaluated consistence with the

arrangements of the MSP something like at regular intervals to confirm that the

systems and practices created under the standard are proper and followed.

Auditor: The compliance audit shall be conducted by at least one person

knowledgeable in the process.

Audit Report: A report of the findings of the audit shall be developed.

Response to the Audit Findings: Employers will immediately determine an appropriate response to each of

the compliance audit findings and document and document that the deficiencies

have been corrected.

Retention of Audit Report: Employers must retain the two most recent

compliance audit reports.

Management review: Management must demonstrate their commitment toward

effective implementation and monitoring of PSM programme.

- Regular management review including action follow up from previous reviews.

- Review process safety leading and lagging indicators

- Review PSM audit findings and action plan

- Review PSM elements gap analysis and action plan

14. Trade secretes

Ensure all relevant

information must be made available by employers to all those people who are

participated and consulted in development of emergency response plan in

consistence with hazard analysis. necessary information to all responsible

persons who must comply the process safety information, those responsible for

developing the operating procedures, performing incident investigations, and

compliance audits, without regard to the possible trade secret status of such

information. Nothing in PSM, however, prohibits the employer from requiring

those persons to enter into confidentiality agreements not to disclose the

information.

Conclusion:

Process Safety management is applicable in highly

hazardous industries which handle hazardous chemical at or above the specified

threshold quantity. Industries viz. Retail facilities, Oil or Gas well drilling

or servicing, normally unoccupied remote facilities are excluded from scope.

There are several benefits of process safety

management viz. ensures safe workplace for workers, reduces Risk to nearby

community, reduces Risk to adverse environment impact, increases assets

reliability with reduced downtime &

losses, ensures high score in International Safety Rating System, provides

a powerful risk management tool, reduces Insurance premium, integrates with

existing Quality, Environment & Safety Management System, facilitates

structured approach towards business, management with better controls, etc.

How to measure performance of process safety management

Reporting of Process Safety Incidents and near misses

Safe Mechanical completion, pre-commissioning, startup | Oil and Gas Facility

You may find affiliate

links in this article. This means that if you click on a link and purchase any

of the products on this page, we may receive a commission, at no additional

cost to you, It does not affect our knowledge sharing, opinions or reviews. Everything

we do is benefit for you as the reader, so all our knowledge sharing, reviews

are as honest and unbiased as possible.

Sir, thank you very much for sharing such detail information on process safety management

ReplyDeleteThanks

Deletewhat is alram system

ReplyDeleteIf something wrong with basic process safety system, There is role of alarms

DeleteSir, what is diffence between Hazop and Hazid

ReplyDeleteHazard and operability (HAZOP) is a technique used to identify both potential hazards and potential operability problems due to deviation in the design intent. It helps to review the design intent of the particular installation or process system by applying guide words related to the parameters of each process to discover the causes of deviation, adequacy and effectiveness of the safeguards and then recommend controls. Use a risk matrix to determine the probability and consequences of failure.

DeleteHAZOP is generally conducted for new facilities, modification to existing facilities through MOC, and every 5 years for operational facilities.

Hazard Identification (HAZID) is a technique used to identify hazards based on standard checklists prepared with reference to best industry practices, standards, rules and regulations, experience and best engineering practices. Provides input to the primary risk assessment for credible events or scenarios.

very informative

ReplyDeleteThanks for appreciation

DeleteReally impressed! Everything is very open and very clear clarification of issues. It contains truly facts. Your website is very valuable. Thanks for sharing. ספרינקלרים

ReplyDeleteThanks for a compliment

DeleteI would like to thank you for the efforts you have made in writing this article. I am hoping the same best work from you in the future as well. In fact your creative writing abilities has inspired me to start my own Blog Engine blog now. Really the blogging is spreading its wings rapidly. Your write up is a fine example of it. lose 60 pounds in 4 months

ReplyDeleteThanks

DeleteThanks for your insight for your fantastic posting. I’m glad I have taken the time to see this. Grass fed ghee

ReplyDeleteThanks

DeleteOh dear. Essay time again, would it be? And you've the common cramps and palpitations? You will discover 3 places where writer's block starts. There's a chance you're at one of them now. this link

ReplyDeleteThanks for appreciation

ReplyDelete